MASDA shines at 2024 Yongkang Door Fair: Lead the Upgrade of Door Industry Manufacturing

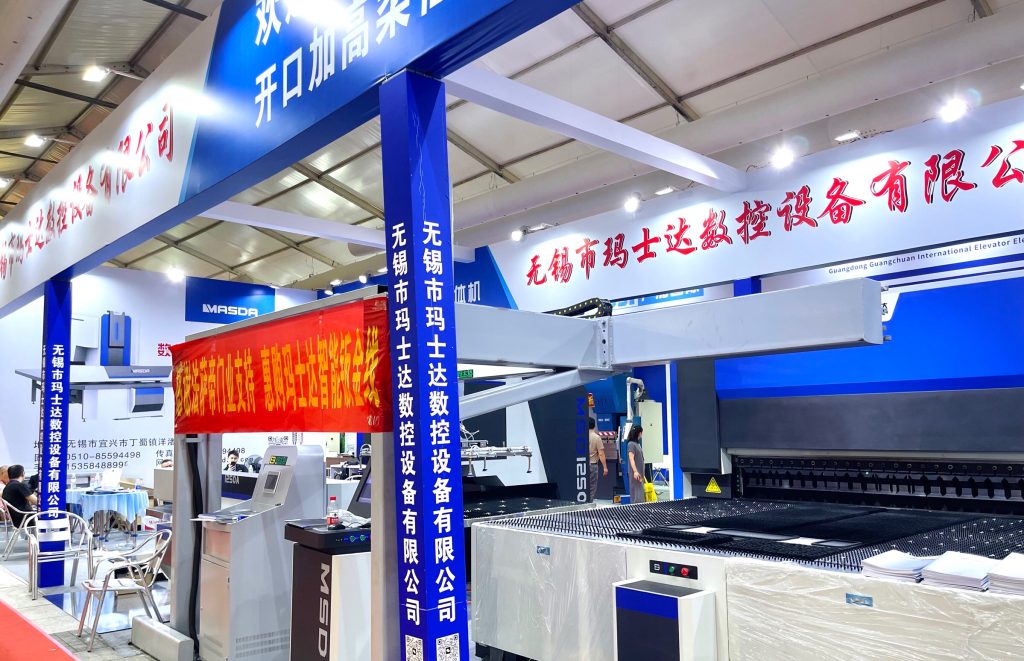

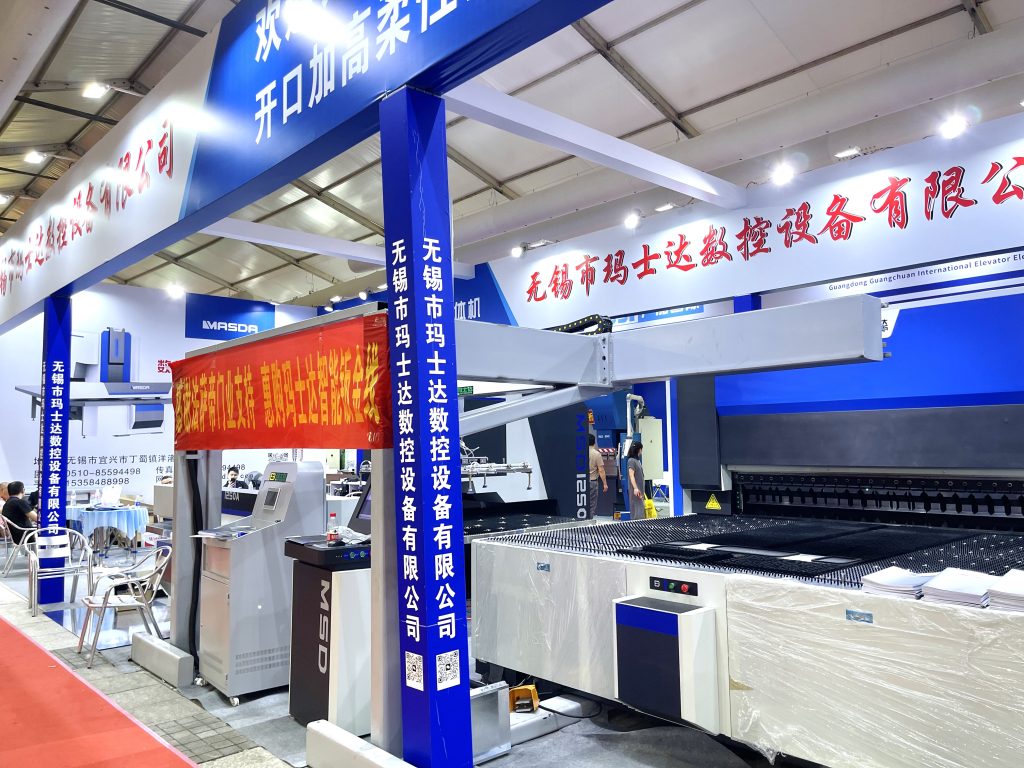

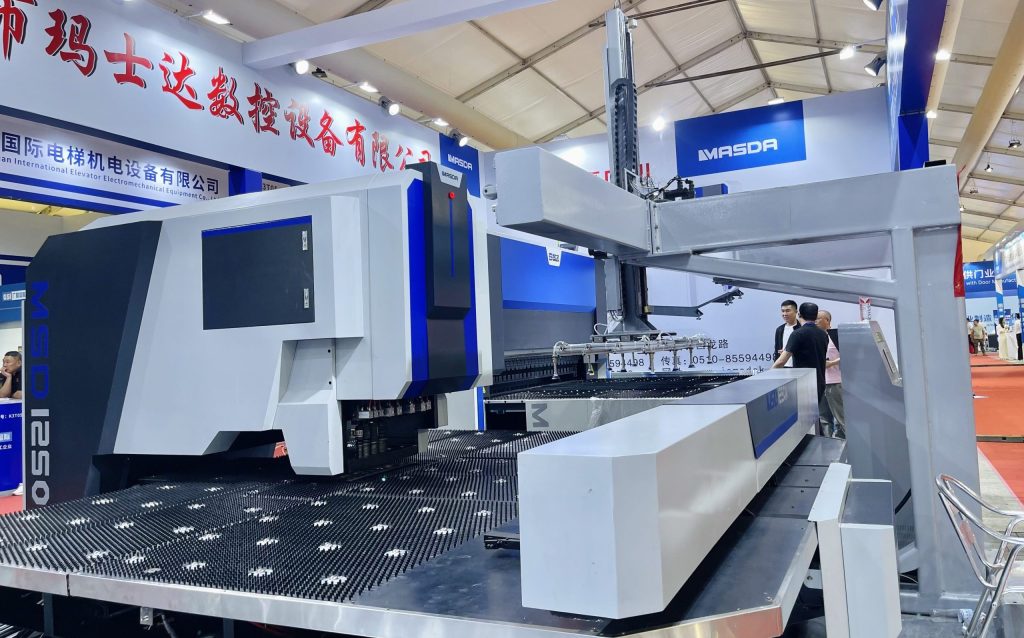

From May 26 to 28, 2024, Masda brought with it its own fully automated bend machine and number of strokes, fangs, and Hydraulic three-in-one CNC punch appeared in the 16th China (Yongkang) International Door Industry Expo (hereinafter referred to as “Yongkang Door Expo”) held in Zhejiang Yongkang international convention and exhibition center, With intelligent and highly efficient innovative technologies, the exhibition became the focus of the company, demonstrating its leading strength in the field of metalworking equipment.

Background of the exhibition and industry opportunities

The Yongkang Door Fair is the largest and most influential industry event in the door industry in China. This exhibition, with the theme of “Intelligent, Green, and Integration,” attracted 947 exhibitors from 22 provinces, autonomous regions, and 22 countries and regions overseas. It is the core position for the upgrading of door technology and market expansion. With the surge in consumers’ demand for customized and diversified door products, the problems of “process dispersion, low efficiency, and precision fluctuation” in traditional sheet metal processing are becoming more and more prominent. Masda’s integrated intelligent production line directly addresses the industry’s pain points, and promotes the transformation of door enterprises from “manufacturing” to “intelligent manufacturing” through technological innovation.

Core exhibits and technical highlights

1. Completely automatic bend machine: intelligent sheet metal processing innovation

Masda’s fully automatic bend machine has become a star product in the field of sheet metal processing in the door industry thanks to the self-developed system and the multi-axis interconnection technology.

Modular design: suitable for large quantities, various types, to meet the security door, fire protection gate and other complex sheet metal parts customized processing.

2. Numerical rushing, dental abrasion, hydraulic three-in-one CNC punch : an example of process integration.

The equipment breaks the limitation of traditional single functions and integrates three processes: “numerical stamping “、“precision dental cutting ”and “hydraulic molding ”.

Process integration : By collaborating with multiple workplaces to achieve “one assembly, multi-process completion,” reducing equipment occupancy and human intervention, especially for sheet metal processing such as door locks and hinge holes.

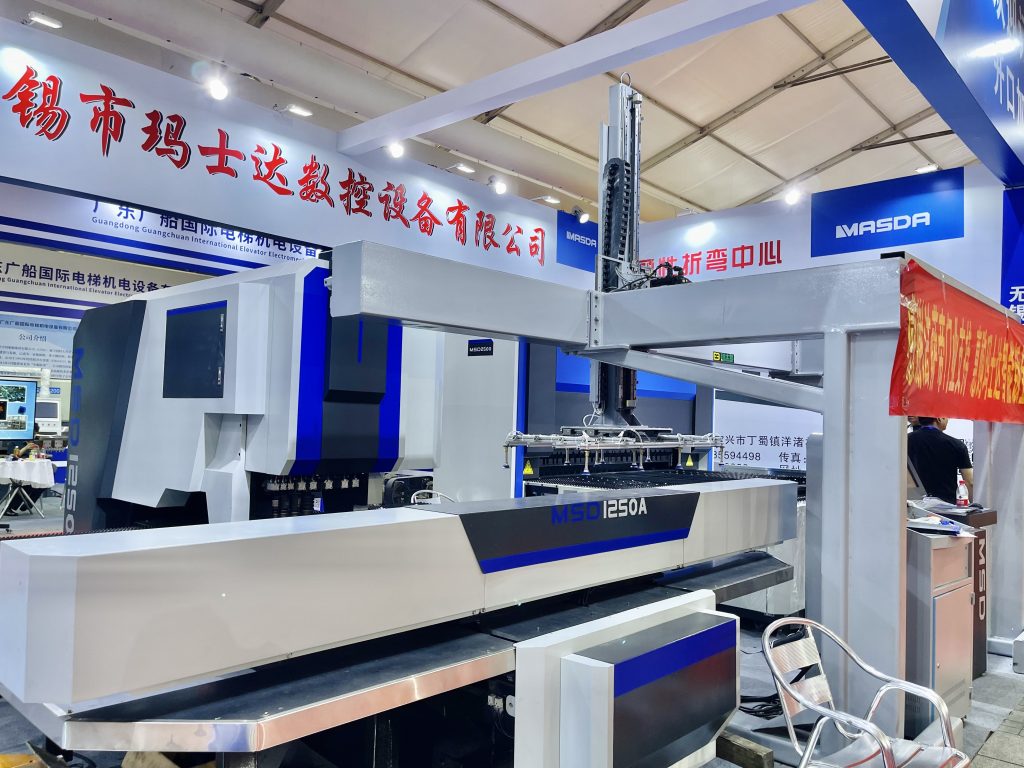

3. Fully automated, integrated intelligent production line.

Robotic arm intelligent collaboration: high-speed heavy-duty robotic arms and automatic benders, The seamless interplay of the CNC milling machine enables the unmanned operation of the whole process of sheeting automatic loading, precise positioning, bending and molding, stamping and toothpicking, and finished product sorting, reflecting the simplification of the process, improving production efficiency and product stability, and meeting the needs of diverse sheet metal processing.

Market response and industry value

During the exhibition, the Masda booth attracted intensive negotiations including” door manufacturers “,”hardware accessories suppliers “and”overseas buyers “. Many enterprises reached cooperation intentions on site, believing that their equipment is comparable to international brands in terms of “machining accuracy “and “production efficiency “, and has more cost-effective advantages. For example, the modular design of the automatic bending machine significantly shortens the product delivery cycle for the automatic and efficient processing of the door panels; The three-in-one CNC punch helps customers reduce equipment investment costs by more than 30% through process integration.

Industry experts pointed out that the promotion of such intelligent equipment will accelerate the transformation of the door industry from traditional manufacturing to “flexible and automated”, and at the same time, it will meet the energy-saving trend under the “double carbon” goal, providing a new path for the green development of the industry.

Technology Research and Future Layout

Masda will continue to manufacture more efficient and intelligent sheet metal equipment to help more sheet metal enterprises improve their productivity.

As a benchmark enterprise of China’s high-end CNC equipment, Masda used this year’s Yongkang Door Expo as a window not only to show the core strength of domestic intelligent equipment, but also to demonstrate its mission to help the door industry “upgrade to intelligent manufacturing.” Driven by both policy benefits and market demand, the company is expected to lead the global innovation wave of door manufacturing technology and inject new momentum into “China’s intelligent manufacturing.”