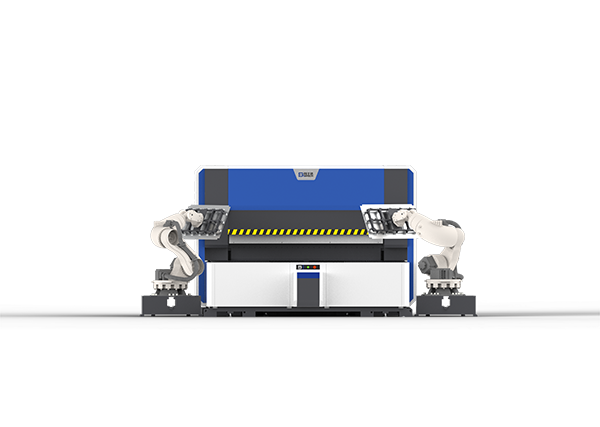

Automatic bending machine

Masda’s intelligent flexible bending center, developed through high-precision machining technology, uti- lizes mold steel for mold production to minimize mold wear while ensuring bending angle accuracy.

The plate is positioned once to complete multilateral bending, and the bending process is completely automated. Full servo drive, precise control, speed can be adjusted. It also consumes less energy and is easy to maintain.

The bending speed is only 0.2 seconds per blade, and the equipment can automatically fold up and down ac- cording to the bending process. Multiple bending requirements can be achieved without changing the cutting tools: combination bending of various angles such as arc, upper edge, and lower edge. Save a lot of labor and mold costs for enterprises.

The mold replacement speed is fast, the operation path is short. The workpiece does not need to be turned over as a whole, so the bending speed is faster and the bending efficiency is extremely high. At the same time, the port can be reserved for the unmanned production system, which can be connected with the robot arm to realize intelligent processing easily.

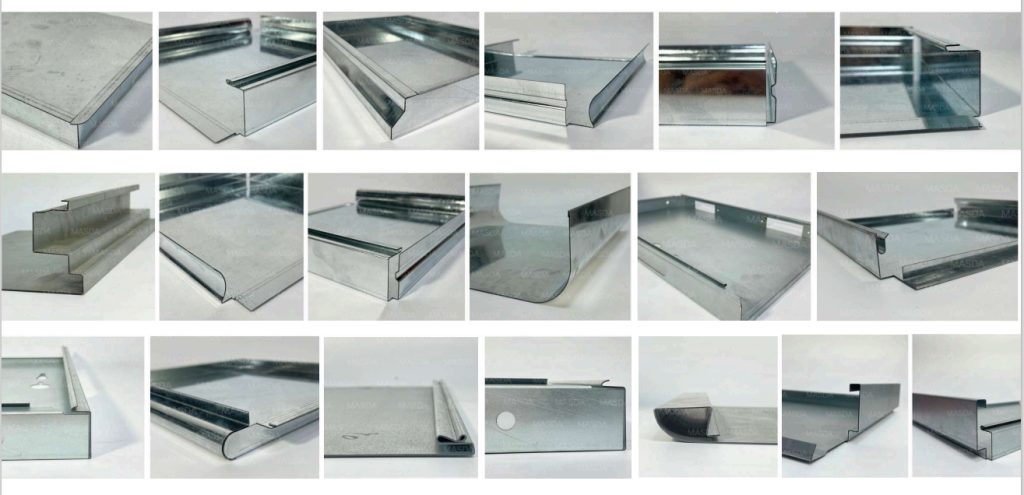

MASDA automatic bending machine-bending sample

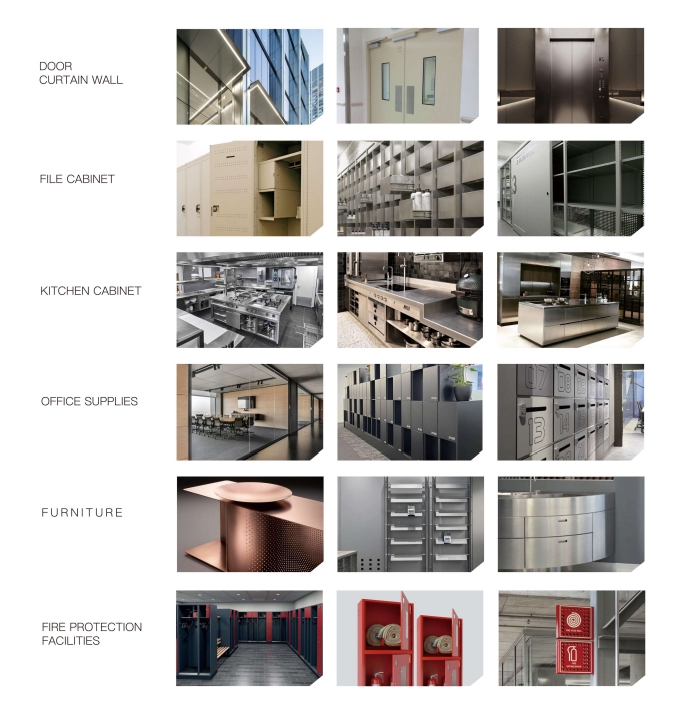

Driven by innovation, MASDA NC focuses on high-quality sheet metal automation equipment. The company has strict quality management and effcient production process, committed to providing customers with high quality products and services.Through continuous innovation and quality assurance, MASDA has won the trust and recognition of our customers. MASDA NC will continue to uphold the concept of brand development and provide more enterprises with intelligent NC equipment solutions.