Development History

2006:From Workshop Breakthrough to Industry Transformation.

When the sheet metal industry stagnated with inefficient traditional methods, Masda’s founder pioneered CNC punch technology development in a dedicated R&D lab, laying the foundation for modern precision manufacturing.

2007: Brand Establishment and Technological Breakthrough . The first NC punch press of Masda was born . and the brand was formally established . With this epoch-making technology . it quickly gained wide attention in the industry .

2008: The company was registered as “Shuo Magnesium Hardware Co.. Ltd.”. and obtained the invention patent of NC punch . which laid a solid foundation for the development of the company .

2009-2010: Expansion of production capacity . product line Masda moved to a new plant . which significantly increased its . production capacity and enriched its product line to meet market demand .

2014: Consolidation of market position and business expansion . The establishment of a branch company to further expand . its business scope marked the consolidation of market position .

2015: Pioneering Industry Frontiers through Innovation,

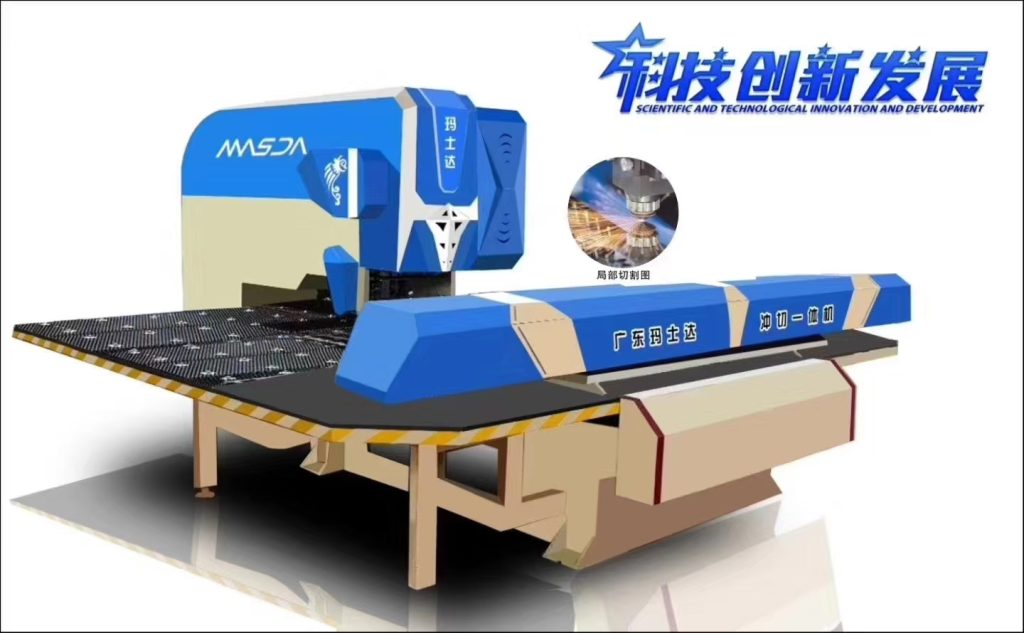

The company’s breakthroughs in automated feeding systems, CNC punch-laser integration, and intelligent shearing machines have cemented its leadership in sheet metal technology, driving the industry toward new frontiers of efficiency and precision.

2017: Focus on R & D and product line enrichment . Jiangsu Masda Branch was established . and started the R & D of the bending center . with increasingly rich product lines .

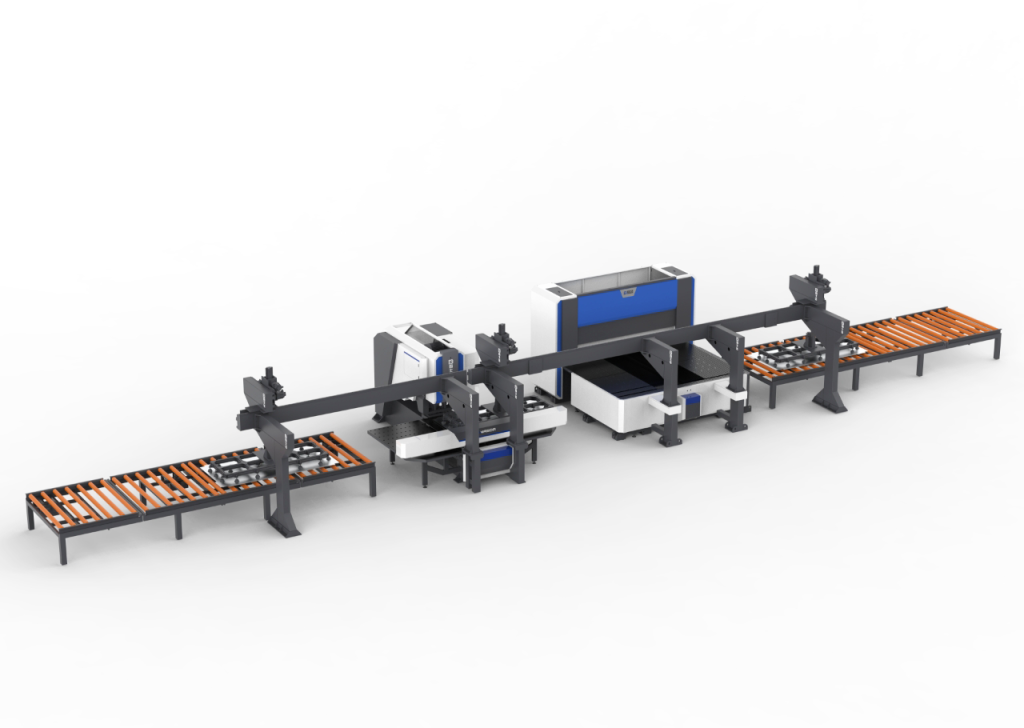

2018: Expansion of production scale and R & D of new products . The new plant was put into use . and the sheet metal roller line and bending center entered the testing and production stage .

2019: Breakthrough in the field of high-end .sheet metal equipment . launching the first generation of hydraulic bending center . formally entering the field of high-end sheet metal equipment .

2020: Production automation is upgraded and . the second generation of hydraulic bending center is launched . which is equipped with mechanical arm to realize production automation upgrade .

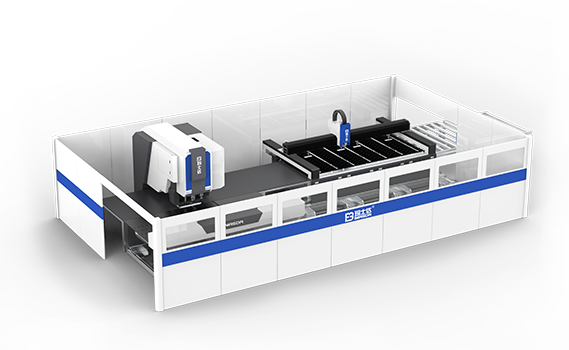

2021: Technological breakthrough and market competitiveness . the third-generation full-servo bending center is released . with the maximum bending width of the equipment reaching 2.5 meters .

2022: The fourth generation of bending center is launched . with technological progress and market leading position . the bending width is increased to 3 meters . and the suction cup system is fully upgraded .

2023:Masda Enhances Production with Intelligent Upgrades:

5th-gen Bending Center boosts efficiency & safety.Tool System upgraded with precision engineering.Automatic Collision Avoidance added for operational safety.Smart Sheet Metal Line achieves full-process intelligence, optimizing productivity.

2024:

Masda achieved breakthroughs in performance and durability:

Sixth-generation Bending Center launched with reinforced structure;

CNC Punch upgraded to integrate digital punching, hydraulic control, and tapping functions;

Sheet Metal Composite Machine seamlessly combines digital punching, hydraulic control, tapping, and laser cutting into a “four-in-one” machining system. marking a dual advancement in efficiency and longevity.

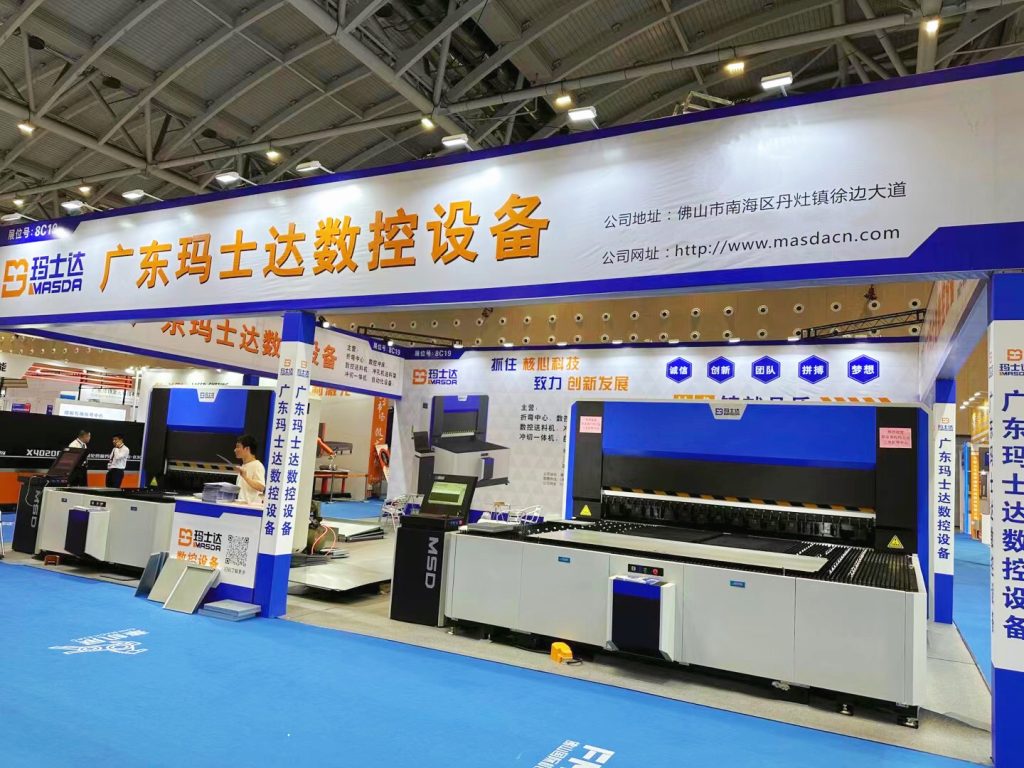

Masda Today: Industry Leader & Innovation Pioneer

As a global frontrunner in sheet metal equipment . Masda drives innovation and delivers high-efficiency solutions worldwide. Committed to advancing industry standards . Masda continues to shape the future of the global metal fabrication market with cutting-edge technologies.