Masda: 18 years of deep cultivation in intelligent manufacturing and sheet metal automation

Today, as the wave of intelligent manufacturing sweeps the world, Masda, founded in 2007, has built a full industrial chain layout covering R&D, production, and services with 18 years of deep cultivation in the industry.

Its independently developed flexible bending center, CNC punch press and other intelligent equipment have not only set off a technological revolution in the domestic sheet metal industry, but also been exported to more than ten countries such as Southeast Asia, the Middle East, and Europe, making “Chinese Smart Manufacturing” a clear mark on the global intelligent manufacturing map.

Three core equipments define new standards for industry efficiency

As a high-tech enterprise with 88 patents, Masda has always focused on the core needs of “intelligent production”.

Its star product, the flexible bending center, breaks the industry record with a lightning speed of 0.2 seconds per cut. The original aluminum suction cup technology ensures the precise positioning of 3.2-meter super-large plates, and cooperates with the intelligent system to achieve multi-angle combination bending, which reduces the cost of mold replacement by 60%.

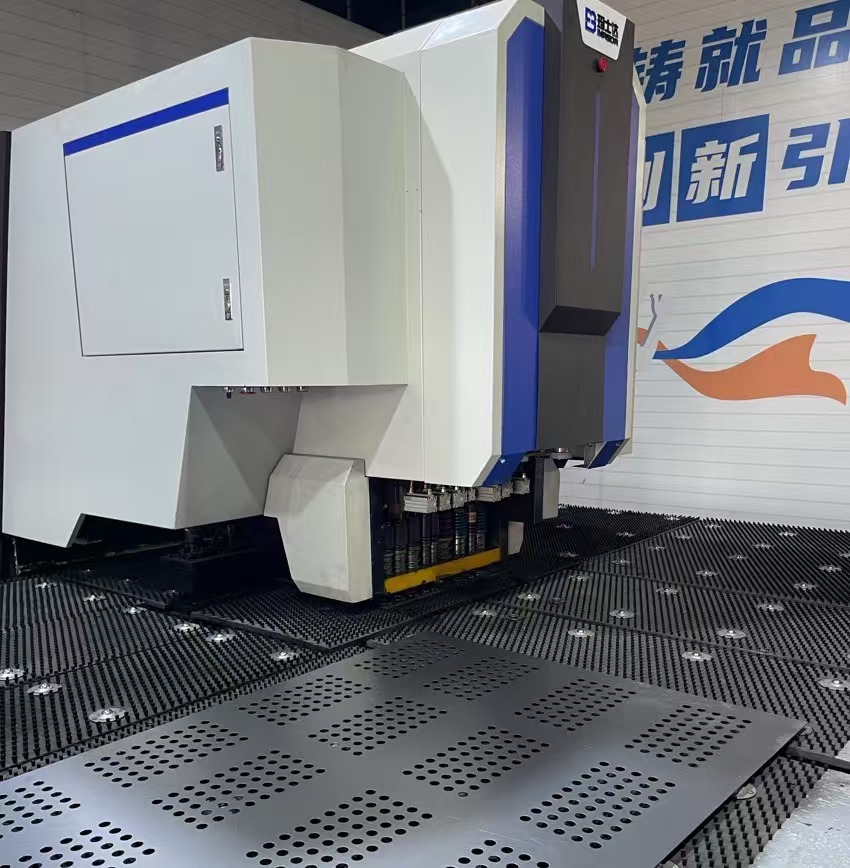

The CNC punching machine with 260 punches per minute uses a straight punching structure to break through the efficiency bottleneck of traditional equipment, and is equipped with a CAD drawing intelligent recognition system to make the complex processing of materials such as aluminum plates and stainless steel smooth.

Even more eye-catching is the four-in-one multifunctional compound machine, which integrates four major processes of digital punching, hydraulic, tapping, and laser into one, truly realizing “one machine to solve all sheet metal processes”.

Global layout makes intelligent production within reach

From smart electric cabinets in Singapore to precision components in Turkey, Masda equipment is deeply involved in the construction of a global intelligent manufacturing system.

Through the coordinated operation of the Jiangsu production base and the Guangdong headquarters, the company has built a supply network radiating Southeast Asia, the Middle East, and Eastern Europe, serving more than 3,000 companies at home and abroad, and creating benchmark cases in more than ten fields such as door industry, kitchenware, and elevators.

Its independently developed Masda system supports a multi-language operating interface, and with the intelligent positioning technology of the beam-type suction cup robot arm, it truly realizes “one drawing for global production”, allowing Algerian fire cabinet manufacturers and Vietnamese office furniture companies to share the same intelligent experience.

![14 {"source_type":"douyin_beauty_me","data":{"infoStickerId":"","capability_extra_v2":{},"imageEffectId":"","pictureId":"2F4B01E8-E91F-4F48-98F2-A17DFF4C6C3D","enter_from":"enter_launch","stickerId":"","capability_key":["portrait"],"filterId":"","product":"retouch","activityName":"","appversion":"11.4.0","os":"ios","playId":""}}](https://www.masdacnc.com/wp-content/uploads/elementor/thumbs/14-scaled-r3zzgvylxp8l9hht9jfzi40argi1qale8kv84hrx6w.jpg)

Technology is universal and the mission of manufacturing power is fulfilled

“Let every enterprise easily upgrade the intelligent production line” is not only the corporate slogan, but also the technical development principle of Masda.

Through modular design, personalized solutions can be provided according to customer needs. This “building block innovation” concept not only meets the whole line automation needs of large enterprises, but also provides a gradual upgrade path for small and medium-sized manufacturers.

Just as its development philosophy of “quality builds the foundation and innovation leads to the future”, Masda is promoting the global sheet metal industry to evolve towards high efficiency, energy saving and sustainability through continuous technology universalization.

Standing at the new outlet of intelligent manufacturing, it is proved with real patented technology that the real industry leader should not only forge cutting-edge equipment, but also transform the results of innovation into affordable productivity.

As more and more “Made in China” appear in the smart workshops of the world’s factories, China’s smart manufacturing is writing its own global narrative.

RELATED NEWS