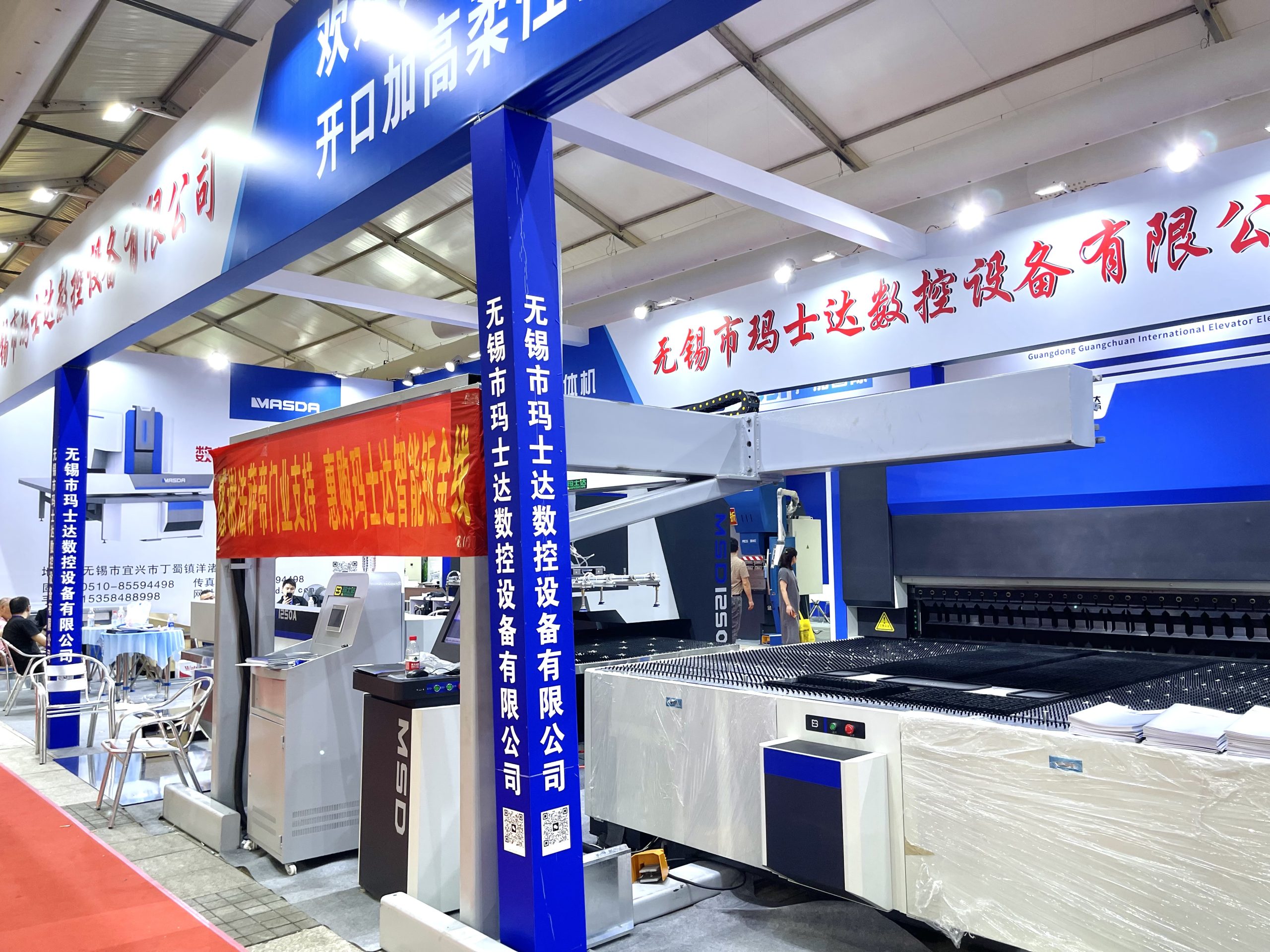

Masda’s intelligent sheet metal equipment empowers four core areas and unlocks new possibilities for efficient production

Today, as the wave of intelligent manufacturing sweeps the world, the sheet metal processing industry is undergoing a transformation from traditional crafts to intelligent manufacturing.

As an innovator in the field of sheet metal equipment, we use flexible bending centers, intelligent CNC punching machines and sheet metal composite machines as the fulcrum to inject efficient production momentum into multiple industries. Let us look at how intelligent equipment reshapes the industry’s production pattern through four typical application scenarios.

1. Building and public facilities: protecting the beauty of urban safety

In the field of door curtain walls and fire protection facilities, the flexible bending center is showing its unique value.

The repeated positioning accuracy of 0.05mm allows the complex curved surfaces of curtain wall decorative lines to be perfectly presented; for safety products such as fire boxes and fire doors, the intelligent compensation system equipped with the equipment can automatically correct material deformation to ensure the processing consistency of key safety components.

2. Power and communication fields: Building the "power veins" of smart cities

When the focus turns to the manufacturing of special equipment such as power cabinets and communication base stations, the combined advantages of intelligent CNC punching machines and sheet metal composite machines are fully demonstrated.

For the electric box and cabinet industry, the equipment supports 0.5-second rapid mold change technology, which can seamlessly switch the processing of installation holes of different specifications; in the production of 5G base station cabinets, the composite processing technology enables the traditional heat dissipation hole processing that requires 5 processes to be formed in one time by a single machine.

3. Industrial equipment and living facilities: making precision manufacturing within reach

From elevator cars to commercial kitchenware, from precision chassis to smart office furniture, our equipment solutions are redefining industrial sheet metal processing standards.

The special mold library developed for the elevator industry is compatible with 30 types of special-shaped guide rail processing; in the field of kitchenware manufacturing, the equipment’s unique anti-scratch process allows stainless steel countertops to achieve a “zero-defect” mirror effect.

4. Emerging field expansion: unlimited possibilities of flexible manufacturing

Facing emerging fields such as new energy vehicle battery boxes and smart express cabinets, the equipment’s multi-material adaptability continues to break through.

The thickness of the processable materials covers 0.5-12mm, and can be stably processed from aluminum alloy to galvanized steel plates. The energy storage equipment housing project that was successfully delivered recently achieved co-production of 38 specifications of products, with a switching time of no more than 15 minutes.

From urban infrastructure to industrial manufacturing, from public facilities to cutting-edge technology, we have always been committed to promoting the upgrading of the sheet metal processing industry with innovative equipment.

In the future, we will continue to focus on the development direction of intelligence and flexibility, provide partners with more efficient and accurate solutions, and jointly open a new chapter in intelligent manufacturing.

RELATED NEWS