How does the sheet metal processing factory maintain and maintain the equipment?

In the sheet metal processing industry, the state of the equipment directly affects the production efficiency and product quality. Therefore, for sheet metal processing plants. equipment maintenance and maintenance are an indispensable part of daily operations.

First,Key Steps for Equipment Maintenance:

Establish a regular maintenance plan as the foundation.Each equipment requires a specific maintenance cycle.Develop detailed plans based on usage frequency, work environment, and manufacturer guidelines.Include daily inspections, routine cleaning, and timely component replacements.Ensure equipment remains in optimal condition consistently.

Secondly,Key Measures for Operator Training:

Prioritize comprehensive training for equipment operators Operators serve as primary responsible parties for equipment management.Operational habits and maintenance awareness directly impact equipment lifespan.Conduct regular skill-building sessions and maintenance workshops.Ensure proper equipment usage, standardized practices, and prompt issue resolution.

In addition,Essential Maintenance Practices:

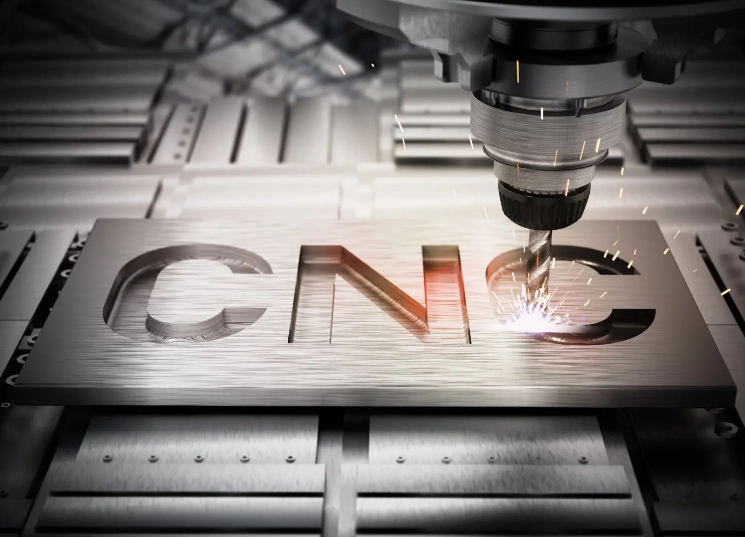

Emphasize daily cleaning and lubrication as critical maintenance steps.Metal shavings, oil stains, and impurities often accumulate during sheet metal processing.These contaminants can disrupt equipment functionality and cause long-term damage.Regularly clean equipment to remove debris and residue.Maintain surface cleanliness as a core task to ensure operational reliability.

At the same time, for parts that need lubrication. lubricants should be added regularly according to the manufacturer’s recommendations to ensure the smooth operation of the equipment.

In addition, it is essential to establish a complete record of equipment failures and maintenance files. Every time equipment fails or undergoes maintenance. detailed records of the failure phenomenon, maintenance process, and replacement parts should be made. so that they can be consulted and analyzed in the future.

These records can not only provide references for the maintenance and maintenance of equipment. but also help sheet metal processing plants better understand the operation of equipment and prevent potential failures from occurring.

In conclusion,Core Maintenance Strategies for Sheet Metal Plants:

Develop a structured maintenance plan for all equipment.Provide regular operator training to ensure skilled and responsible usage.Prioritize daily cleaning and lubrication to prevent contamination.Maintain detailed fault records and repair archives for analysis.Enhance equipment stability and production efficiency through systematic maintenance.Support long-term growth of the sheet metal processing plant with reliable operations.

RELATED NEWS