Upgrade Plan for Sheet Metal Processing Equipment: Annual Cost Savings of 300000 RMB

In the fiercely competitive manufacturing industry, cost control is the core of enterprise survival. Traditional sheet metal processing equipment has low efficiency and high maintenance costs. resulting in losses of hundreds of thousands of yuan annually due to downtime, manual intervention, and material waste.

How to achieve cost reduction and efficiency improvement through technological upgrades? This article reveals a scientifically feasible solution to help you easily achieve the goal of saving 300000 costs annually.

Current pain point: the "hidden cost" of traditional equipment

Efficiency drags down profits: slow processing speed of old equipment, obvious production capacity bottlenecks, and extended order delivery cycles lead to customer loss.

High maintenance costs: Mechanical components frequently malfunction. with an average annual repair cost exceeding 80000 yuan, and downtime losses are difficult to estimate.

High dependence on manpower: relying on manual operation. high error rate, and rework cost accounting for more than 15% of overall expenditure.

Upgrade plan: Four major breakthroughs brought by technological innovation

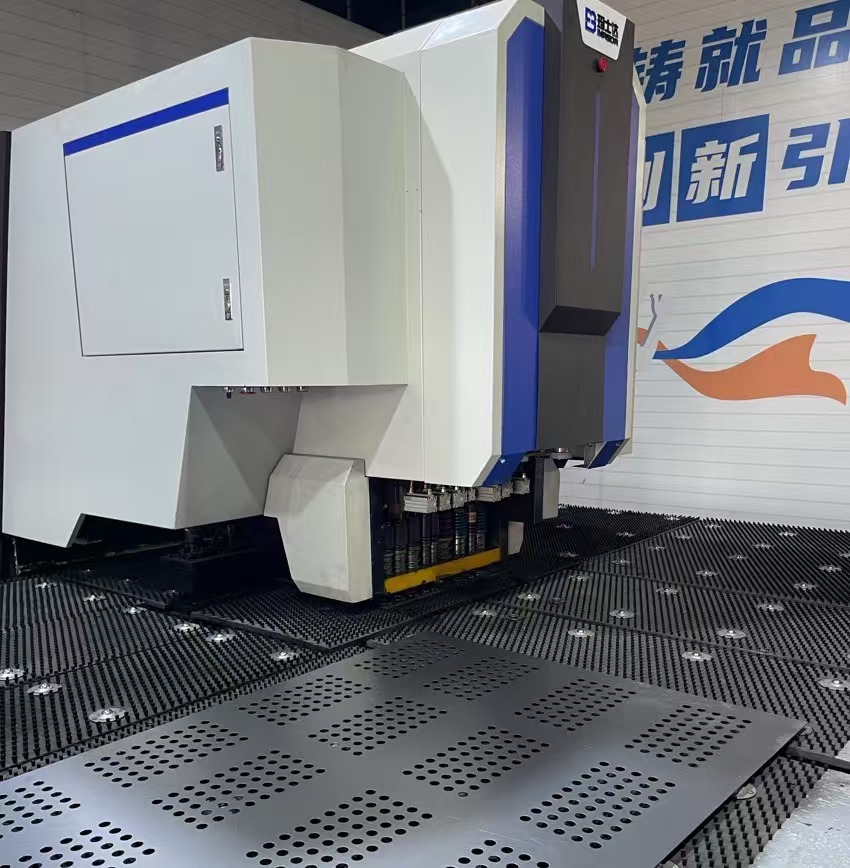

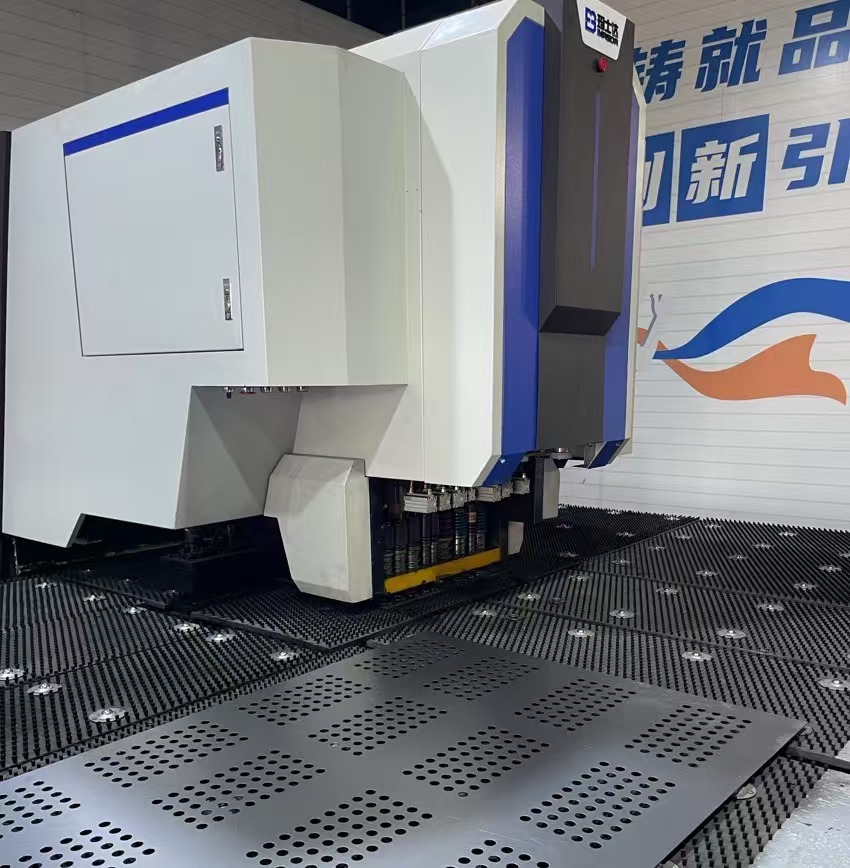

1. Automation system: Efficiency increased by 40%.

Introducing an intelligent CNC system to achieve one click programming and automatic mold changing. reducing manual intervention and shortening single piece processing time by 30%.

2. Intelligent maintenance: reduce downtime risk.

Real time monitoring of equipment status. warning of faults, and reducing downtime from an average of 15 days per year to 3 days.

3. Energy saving design: implicit cost reduction.

By using energy-saving motors and optimizing the transmission system. power consumption has been reduced by 25%.

4. Digital management: precise cost control.

Integrated production data analysis module, real-time tracking of material utilization and labor loss. reducing waste through process optimization.

Technological upgrading is not a cost, but an investment. A scientific equipment upgrade plan can not only save you 300000 yuan, but also reshape the competitiveness of your enterprise. Don’t let old sheet metal processing equipment devour profits anymore – embrace the future of intelligent manufacturing immediately. and turn every investment into visible returns.

RELATED NEWS