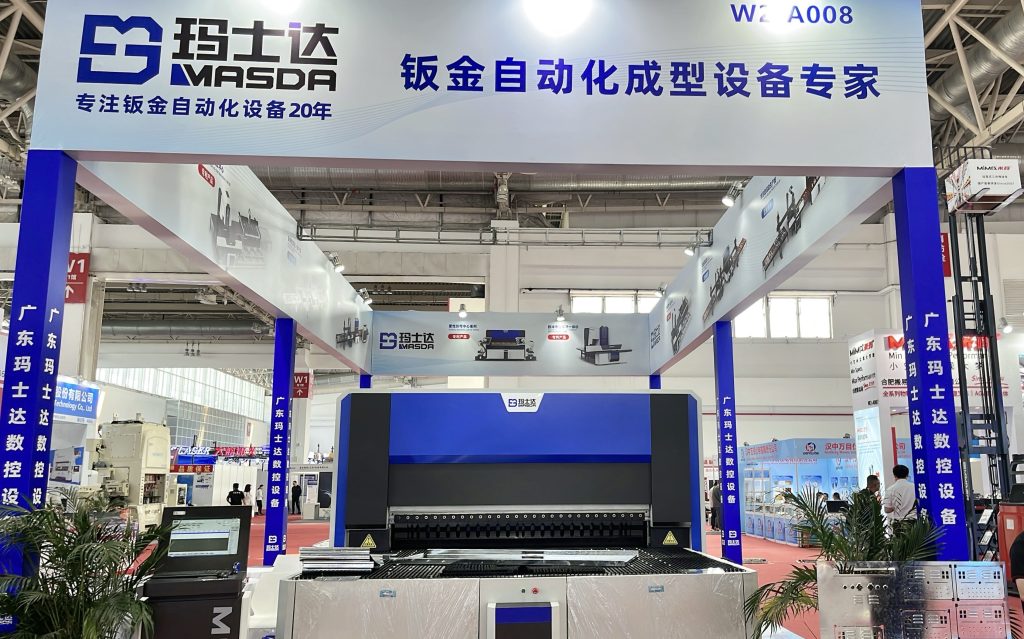

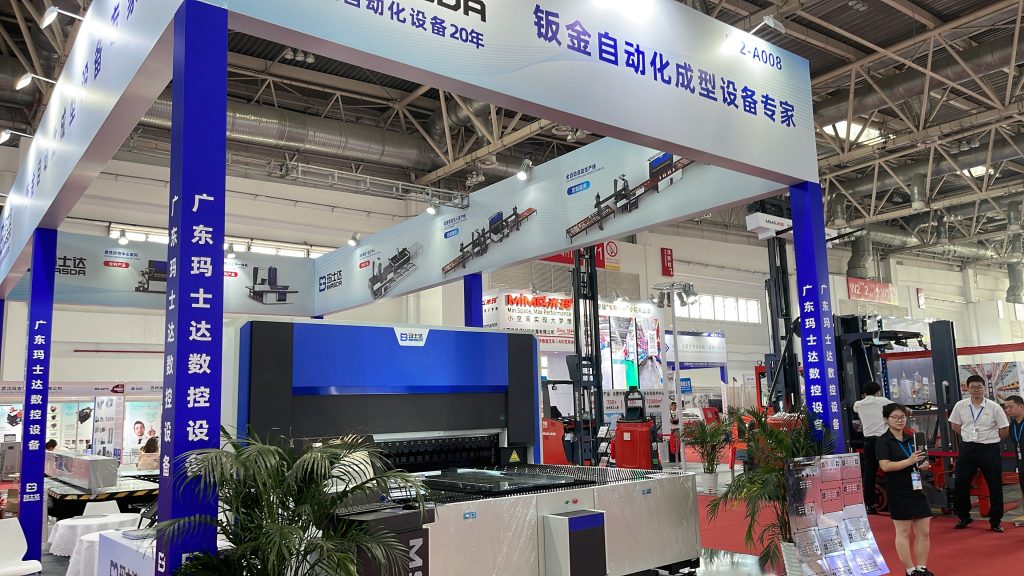

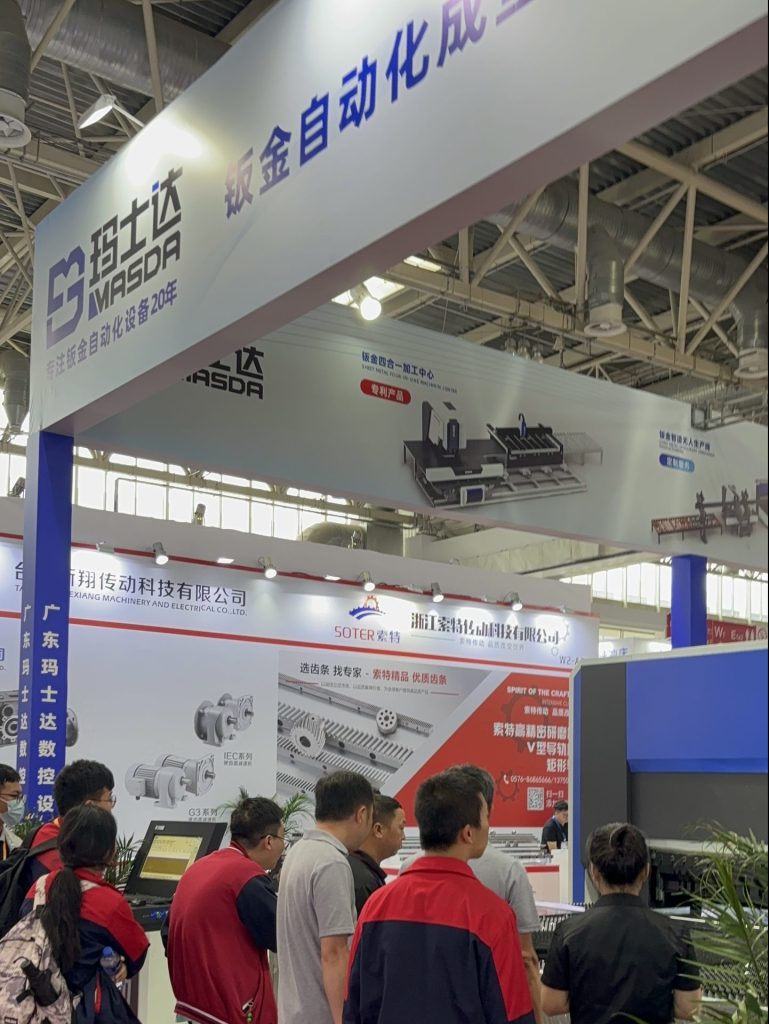

MASDA Shine 2024 Beijing Machine Tool Exhibition

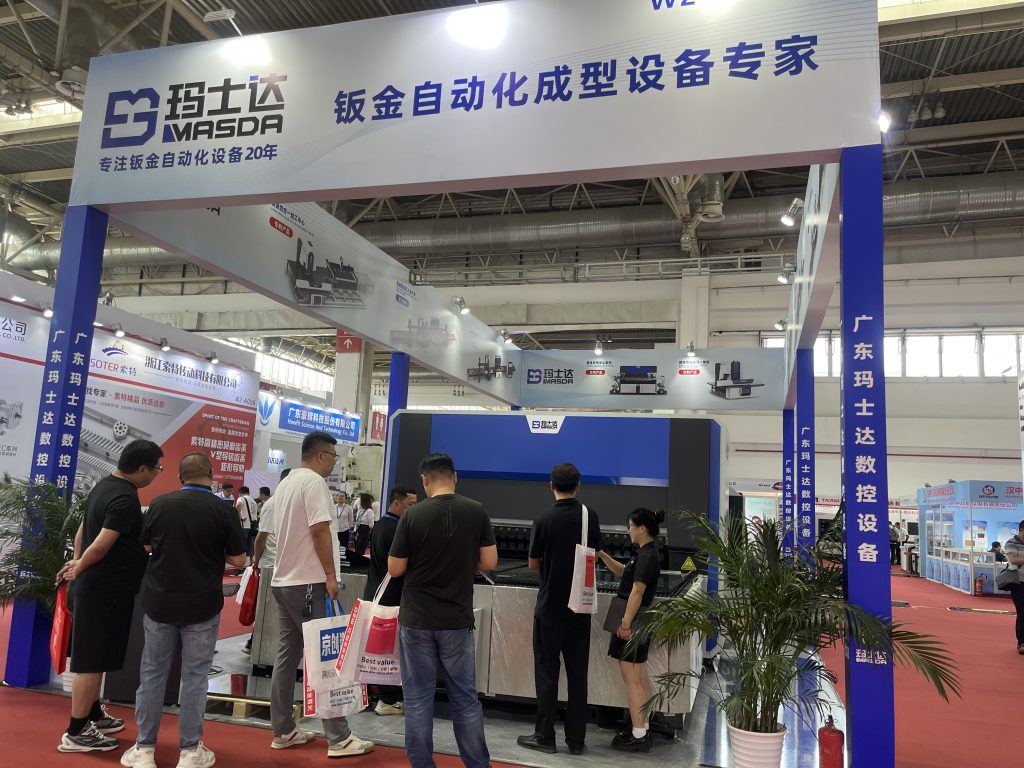

In June 2024, MASDA showcased its self-developed “Automatic Bending Machine” and “Hydraulic 3-in-1 CNC Punching Machine with Attack Tooth” at CIMES 2024 in Beijing.The innovative technologies and intelligent solutions positioned MASDA as a spotlight of the exhibition.This debut reinforced the company’s leadership in the metal forming equipment industry.

Exhibition spectacle and industry background

The China International Machine Tool & Tools Exhibition is one of the largest machine tool industry events in Asia. bringing together the world’s top manufacturers and cutting-innovative technologies

With the theme of “Intelligence, Green and Integration”, this exhibition attracted more than 1,500 exhibitors. covering CNC machine tools, industrial robots, automation systems and other fields, and became a vane to observe the development of China’s high-end equipment.

MASDA participation in this exhibition not only meets the urgent needs of the national “manufacturing power” strategy for high-end equipment. but also responds to the industry’s expectations for flexible production and intelligent upgrading through innovative products.

Core exhibits and technical highlights

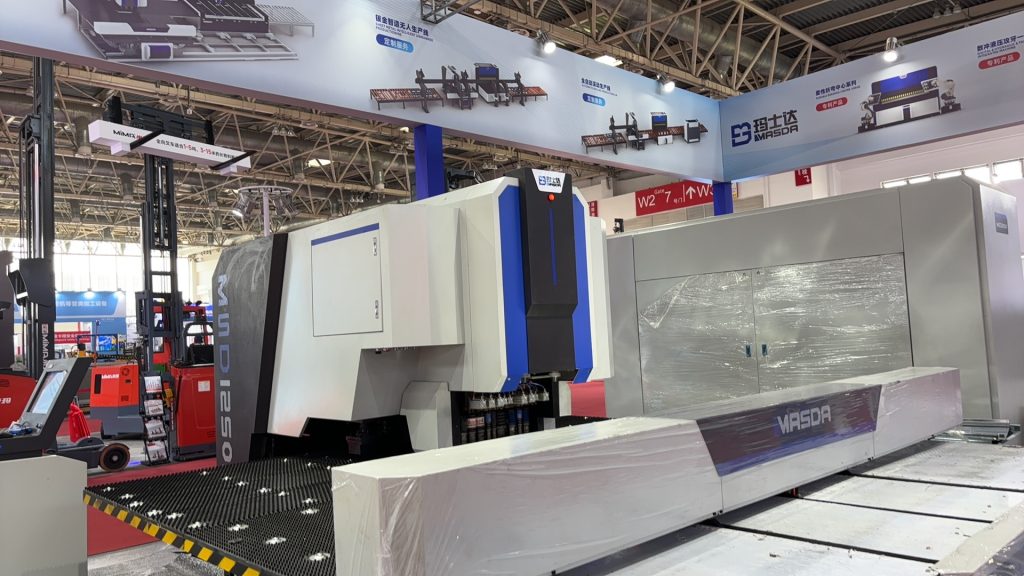

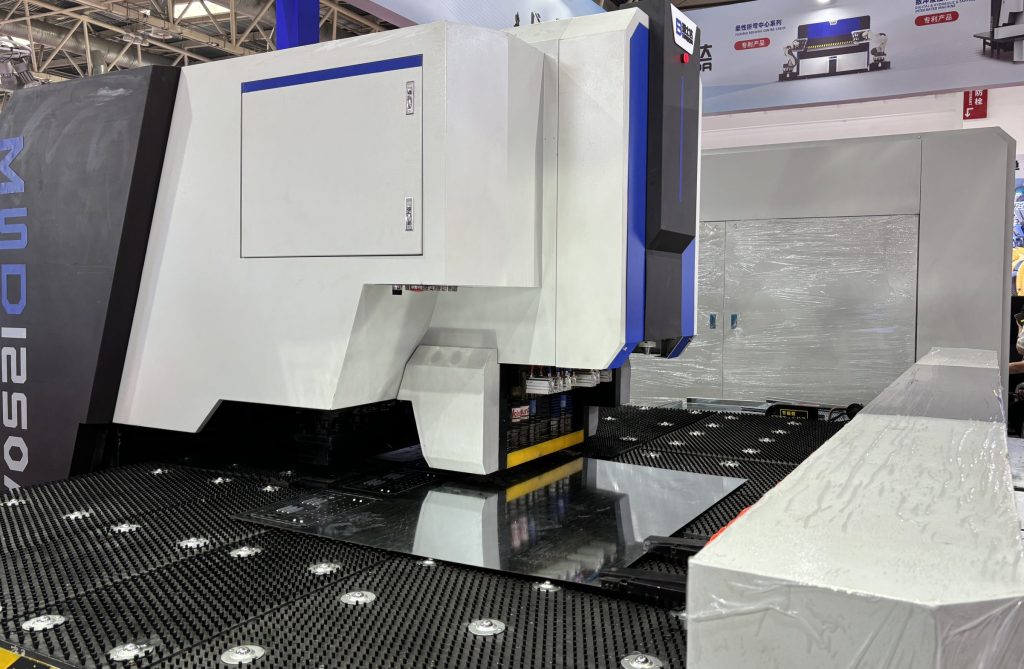

1. Fully automatic bending machine: intelligent industrial innovation

a. The Masda bending center adopts a high-strength welding structure. the main structure is stable and has a large elastic mechanics, the equipment is more stable and durable. and the service life is long. Heat treatment to remove internal stress, strong rigidity. large ton, to ensure the bending accuracy, reliability and durability of the machine tool.

b. The Masda bending center adopts a patented suction cup, which is convenient for feeding and more stable and accurate. It provides stronger torque for thin plates, large plates. thick plates and other plates, while the vacuum suction avoids damage to the surface of the material.

c. Self-developed system, lifetime free upgrade, main control stable operation. can save thousands of files without lag. Graphical programming operation is simple, can be learned in 2-3 hours. Open port, can be matched with robotic arm to build an unmanned production line. realize automatic loading and unloading.

d. The multi-sided bending of the sheet metal is automatically completed in one positioning. and the universal bending mold can easily complete the combination bending of upper bending. lower bending, curved bending, and edge bending. The bending speed can be adjusted, and each stroke is only 0.2 seconds.

2. Three-in-one CNC punching, threading, and hydraulic press: a model of multi-function integration.

This equipment breaks through the limitation of the traditional single function, integrating three processes of CNC punching, precision threading and hydraulic molding into one.

Technology Research and Future Layout

MASDA said that it will continue to focus on the deep integration of “high-end CNC systems”and “industrial Internet”. and plans to launch a next-generation device that supports 5G remote control in 2025.

As a benchmark enterprise in China’s high-end equipment manufacturing, Masda uses this exhibition as a window not only to show the core strength of domestic machine tools. but also to demonstrate the industry’s ambition of “creating the future.”.

Driven by both policy benefits and market demand, the company is expected to lead the global innovation wave of metal forming equipment and inject new momentum into “China’s smart manufacturing.”

RELATED NEWS